Our offer

Engineering

At HYCCO, engineering is our innovation engine.

From initial concept to optimized design, our team specializes in crafting lightweight composite bipolar plates and stack components. We guide you through every step: prototyping with real materials, flow-field simulation (CFD), and structural analysis (FEA), ensuring each design meets cost, performance, and manufacturability targets.

Our focus on integrated design-to-manufacturing reduces development risk and accelerates timetomarket.

Stack CoDevelopment

HYCCO doesn’t just supply parts –

we co-develop stack systems with you

01

Collaborative design

Our experts work directly with your team to co-optimize plates, stack architecture, sealing strategies, and MEA integration

02

Pilot assembly & testing

We support prototype stack assembly, validation, durability and performance testing in collaboration with OEMs and Tier One, research labs, or pilot integrators.

03

Scalability planning

we ensure designs are transfer-ready for larger manufacturing volumes, considering tooling costs, cycle time, and supply chain throughputs

04

Supply chain acceleration

leveraging our hydrogen network, we help source critical components, reduce reliance on scarce materials, and smooth pilot-to-volume transitions.

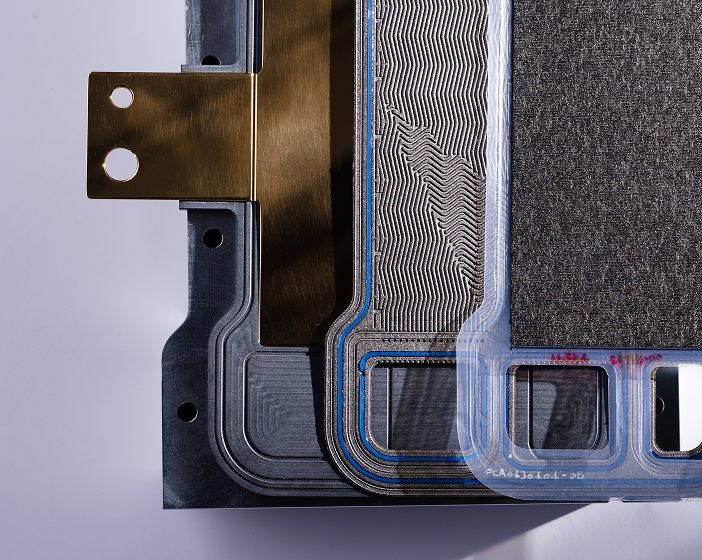

Bipolar Plate Production

We produce composite bipolar plates with industrial-grade precision and scalability

Advanced materials

Carbon-fibre thermoplastic composites tuned for corrosion and temperature resistance, to match your electrochemical device.

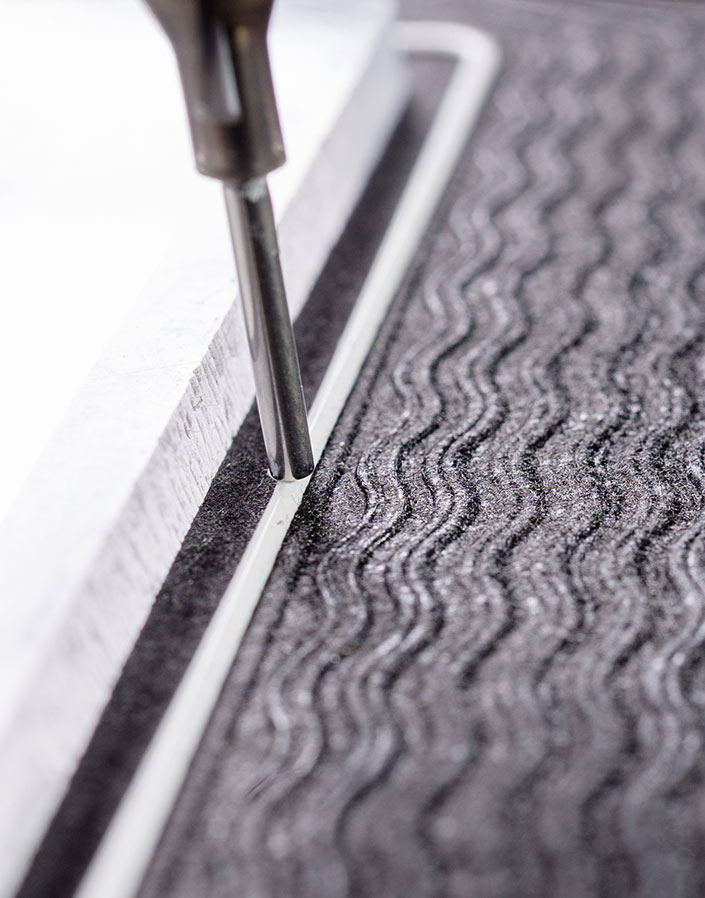

Optimized Thermocompression Forming

Our bipolar plate shaping is performed using an optimized thermocompression process designed for high repeatability and minimal takt time. This approach ensures consistent plate quality while keeping production cost-effective and scalable — ideal for transitioning from prototype to pre-series and industrial volumes.

High-Precision CNC Trimming

After forming, plates are trimmed using high-precision CNC systems, allowing for tight dimensional tolerances and fast design iterations. This flexibility makes it possible to adapt rapidly to new stack architectures and flow-field geometries during prototyping and validation phases.

It Doesn’t Stop Here.

From Plate to Stack, Fully Integrated

Assembly

Plates are bonded using high-precision dispensing systems, ensuring uniform adhesive distribution and strong, consistent adhesion.

Sealing

Custom seal patterns are applied via automated dispensing, tailored to a wide range of MEA and stack configurations. We offer multiple qualified sealant options, to match your operating conditions, fluid exposure, and compression needs.

Quality and part traceability

At HYCCO, quality is built into every step of the production process. Each bipolar plate is tracked from raw material batch to final qualified product, ensuring total traceability and consistent performance.

What’s included in our quality workflow?

Our seamless production flow is designed for both small-scale prototyping and volume manufacturing, enabling a cost-efficient ramp-up when you’re ready.

- ASR measurement for every plate (electrical conductivity check)

- Dimensional control using precision optical and laser tools

- 100% leak testing via air pressure decay method

-

Automated logging of material lot, process parameters, and test results

-

Each finished plate is delivered with its own digital qualification sheet, giving your engineering and quality teams the data confidence needed for traceability, certification, and stack integration.

Why HYCCO?

What truly sets us apart

Composite expertise

Lightweight, corrosion- and heat-resistant plates

Integrated engineering

Faster design cycles, lower risk

Turnkey production

From prototypes to scalable manufacturing

Stack-level partnership

Co-design, test, scale – all under one roof

Ecosystem access

Component sourcing, partner network, accelerated development