Pioneering scalable innovation for a hydrogen-powered world

At HYCCO, we turn hydrogen’s promise into industrial reality.

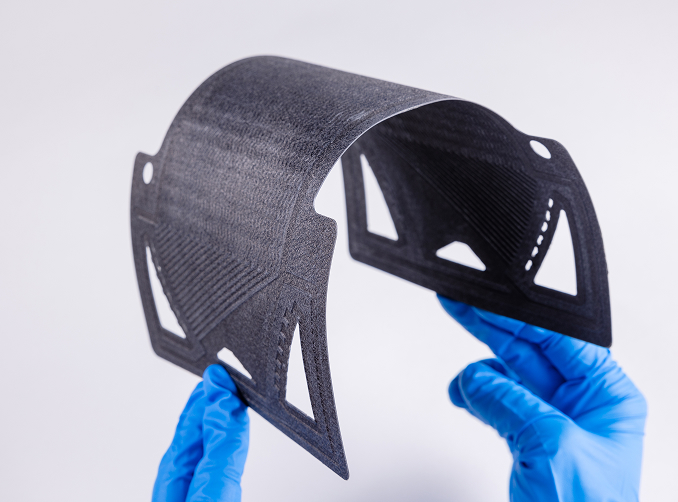

Our patented carbon-fibre composite bipolar plates are lighter, stronger, and built to last—unlocking new standards of performance and efficiency for hydrogen systems at scale.

Whether powering the next generation of aircraft, trucks, or electrolyzers, HYCCO’s technology removes key barriers to adoption — enabling hydrogen to become the backbone of a resilient, low-carbon energy future.

Breakthrough innovation,

made for the real world.

Technology

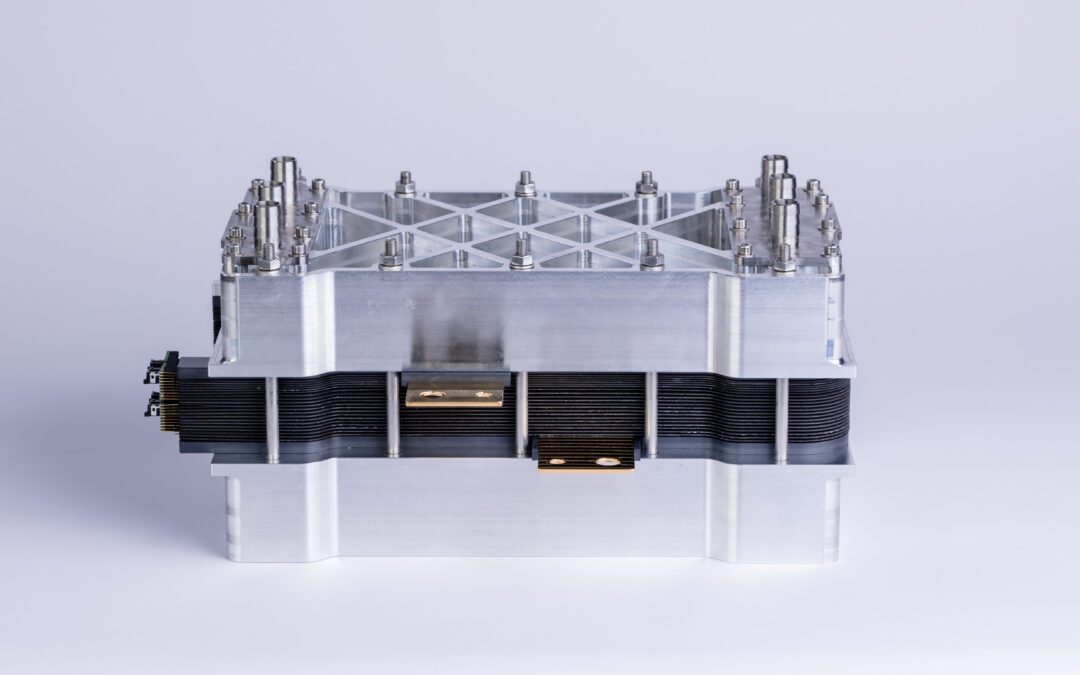

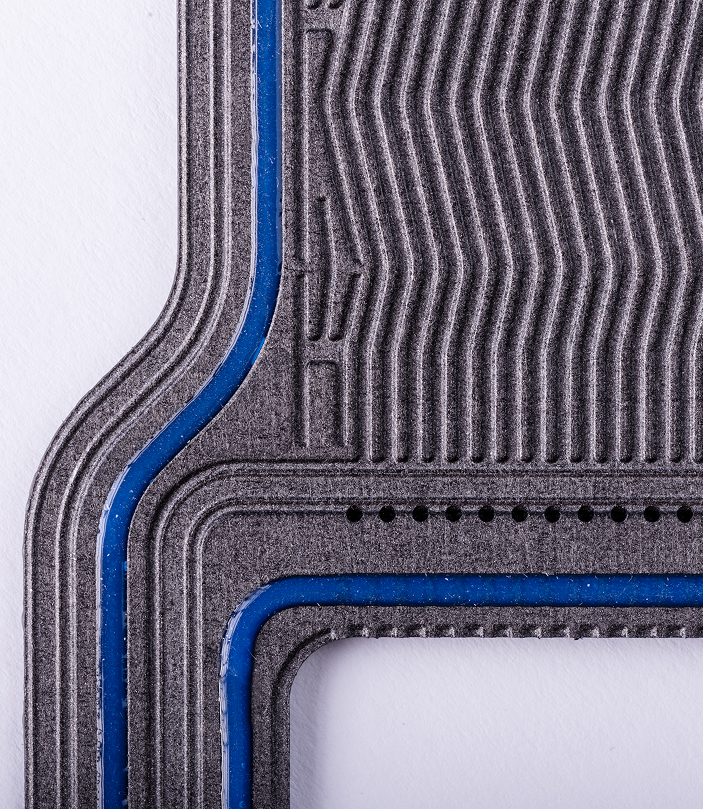

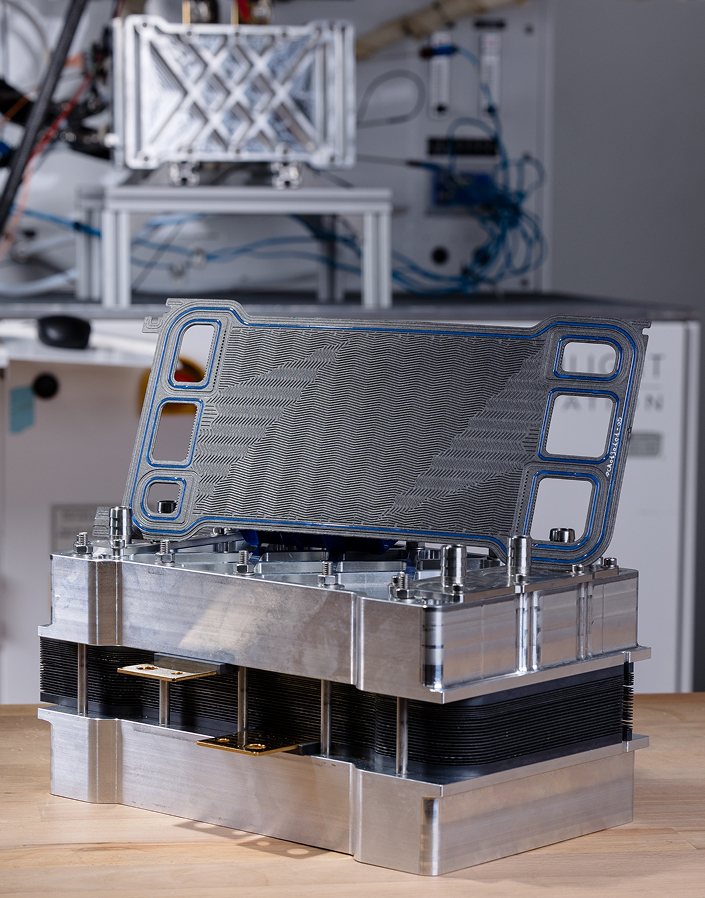

Advanced bipolar plates.

Real-world performance.

HYCCO’s carbon-fibre reinforced composite bipolar plates redefine what’s possible in fuel cell design.

Resistant to corrosion, high temperatures, and mechanical stress, our plates deliver unmatched performance across demanding hydrogen environments — while enabling cost-effective, scalable production

This is not just about better plates. It’s about unlocking hydrogen’s full potential across production, storage, and end-use.

Why HYCCO plates stand out?

Electrochemical Systems

Across the hydrogen value chain, HYCCO delivers.

HYCCO bipolar plates are engineered to support a wide range of electrochemical systems, including:

Low temperature PEM fuel cell

High temperature PEM fuel cell

REDOX Flow Batteries

PEM Electrolyzers

Applications

UAVs & Drones

Ultra-light hydrogen fuel cell plates boost UAV flight times and open the door to new applications.

Aerospace

High-performance fuel cell plates provide lightweight, reliable power for aviation and space.

Heavy-Duty Mobility

Advanced fuel cell plates deliver the power and durability required for trucks, buses, and other demanding mobility applications.

H2 production

Electrolyzers that cut reliance on titanium and other critical materials, making green hydrogen production more scalable and affordable.

Energy Storage

Innovative plate designs boost redox flow battery performance and unlock scalable, long-duration energy storage.

Discover

the applications

Expertise

From design to deployment,

HYCCO delivers industrial excellence.

HYCCO is more than a tech provider, we’re an industrial partner.

With deep expertise in materials science, bipolar plate design, and composite manufacturing, we support clients throughout the full development cycle:

01

Custom design & flow field engineering

02

Prototyping & pilot production

03

Industrial scale-up strategy

04

Technical support & supply chain coordination

We work hand-in-hand with hydrogen ecosystem partners to streamline your development, reduce complexity, and accelerate go-to-market.

Our expert team helps you solve challenges fast — with the right knowledge, network, and tools at every step.

They trust us

Trusted by industry leaders building the hydrogen economy.

Global OEMs, system integrators, and research pioneers choose HYCCO to power their next-generation hydrogen solutions — from mobility to energy storage.