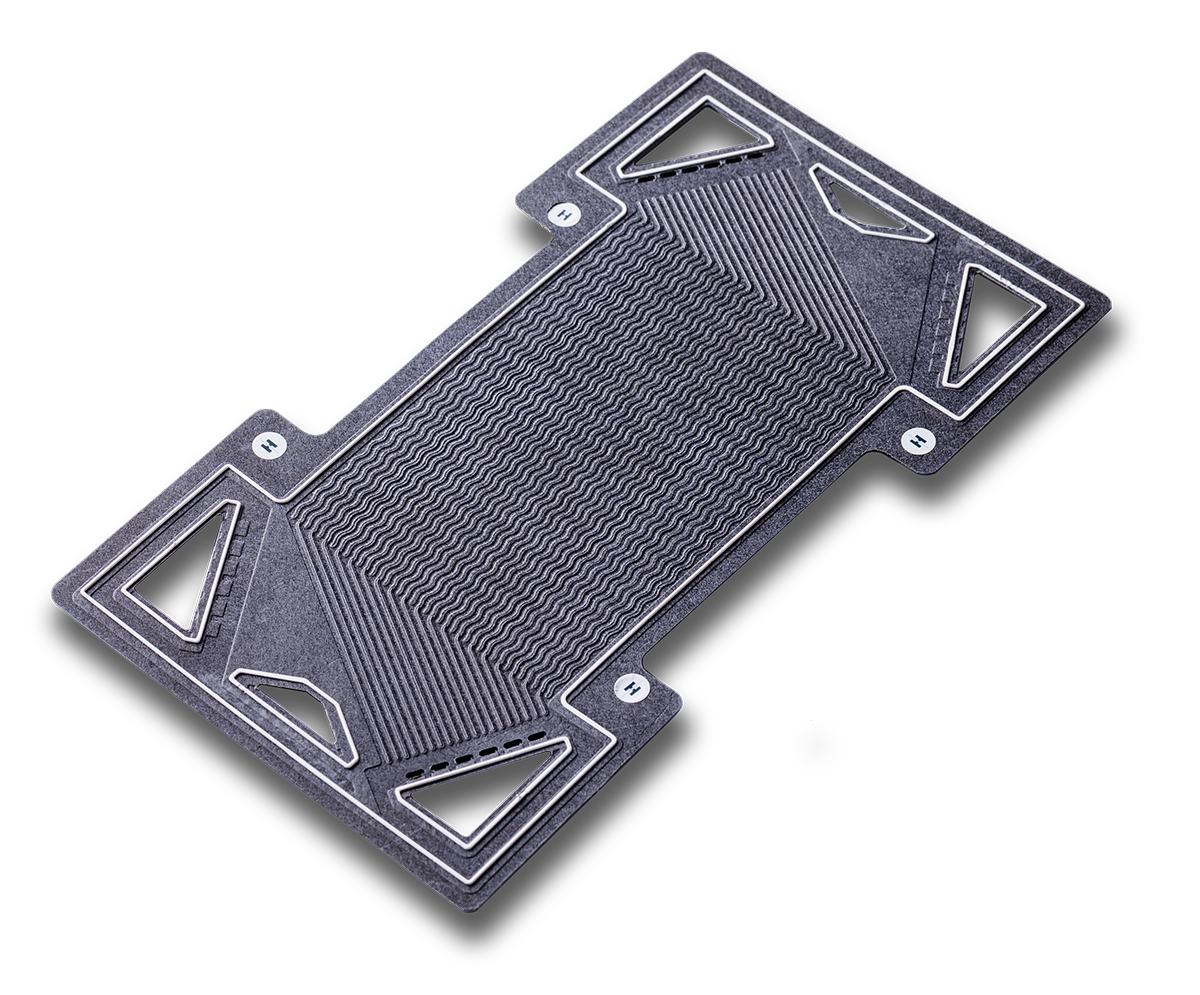

HYCCO can form your complex channel design on plates up to 40x40cm2.

THE NEW GENERATION OF

THE NEW GENERATION OF

Technical Data

HYCCO develops and manufactures conductive, electrochemically resistant and robust fluids separators that can be used as bipolar plates in fuel cells. Plates produced with HYCCO technology are simultaneously light, durable, and compact. Our

developments show an excellent resistance to various corrosive chemical environments.

Our product

Our expertise

HYCCO can form your complex channel design on plates up to 40x40cm2.

HYCCO has developed a welding technology to assemble its carbon fiber bipolar plate. Short cycle time. No glue nor any extra material is needed.

HYCCO is equipped with dispensing system to seal BPP during prototyping phase.*

HYCCO is fully equipped with quality testing equipment to ensure the highest level of qualification of its components.

HYCCO can test up to 2kW HT and LT-PEMFC with full control and monitoring of gas flow, temperature, pressure, gas humidity etc… HYCCO’s bipolar plate material performances and durability are tested in real working environment.

Our production

We have access to state-of-the-art processing and characterization tools to produce, characterize and integrate our technology into fuel cells.

We have set up a prototype production line of 10 000 pieces/year to address flexible small batches. A pilot line with a capacity of 250,000 pieces/year will be deployed within 2023 to address hydrogen markets deployment.